For the last year, when people from the street stop by Sector67 and ask what a hackerspace is, my first stop has been the PPPRS car that sits prominently on our shop floor. It shows off so many capabilities of so many of our members in such a small object, but at the same time is completely ridiculous and fun. It is a physical embodiment of “what the heck we do here”.

This year our PPPRS team took seemingly everything to a completely ridiculous level. This post is going to focus on the car itself. While speed and cornering and acceleration are useful, they are not the core point of this racing series. Our Moxie (style) was through the roof, and will have its own post.

Before I go into details of the car, I have to say that there is one way in which Sector67 completely totally cheats in PPPRS. Our founder, as well as more than a few members of our team are Engineers and former members of the Wisconsin Hybrid (http://vehicle.slc.engr.wisc.edu/) and Formula Hybrid (http://fhybrid.slc.engr.wisc.edu/) teams at UW-Madison. While a lot of what they did may seem like a cakewalk, many hours of hard work and planning were put in. As someone who watched from afar, it was an absolute pleasure to get to learn so much about all this stuff! It only makes sense to show off this crazy contraption to the world in a proper way.

I present, the 2012 PPPRS Championship car: Sector67’s Fauxrarri

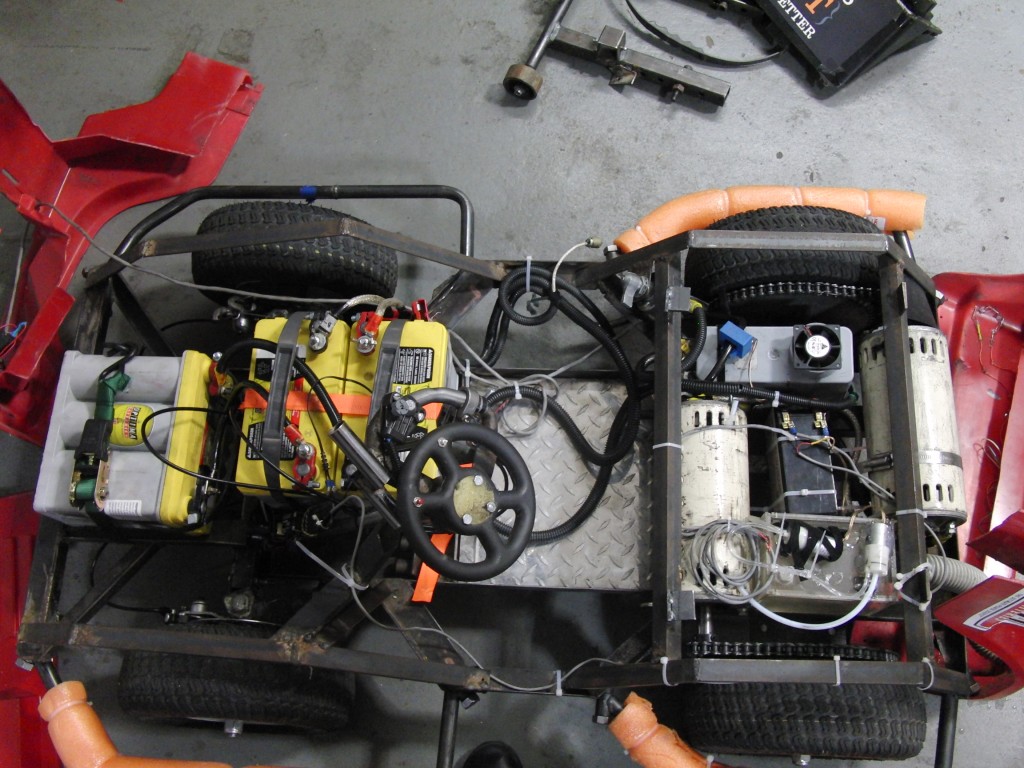

Everything fit under the stock car body, with close to stock seat height.

The car was so fast, it blasted the ‘E’ and ‘i’ right off in Evanston! (If anyone came home with an extra ‘E’ or ‘i’ from the race, please contact PPPRS lost and found)

Those stickers on the car aren’t just for moxie! Our sponsors are awesome, and help make the Fauxrarri and Sector67 so awesome. Special thanks to Optima for the kick-ass yellow-top batteries (more on those later!), and 5Nines technology for helping get the team to all the races.

Lets crack that hood open! Of course, being an electric car, there isn’t much in there except a battery, and some blindingly bright LED headlights. The optima D51 yellow top batteries are, in a word, impressive. Made by a Wisconsin company, They are rated for more than 500 cold-cranking-amps, and can be recharged with no current limit with a constant voltage charger. They can be recharged at 100A from a complete drain in 35 minutes. Due to its cylindrical gel-mat design, they also have unique vibration resistance compared to other types lead acid batteries (as much as 15x according to optima). And are completely spill-proof. Its as if they were built for PPPRS! They retail for around $150/each, and ought to provide power for many many seasons of racing.

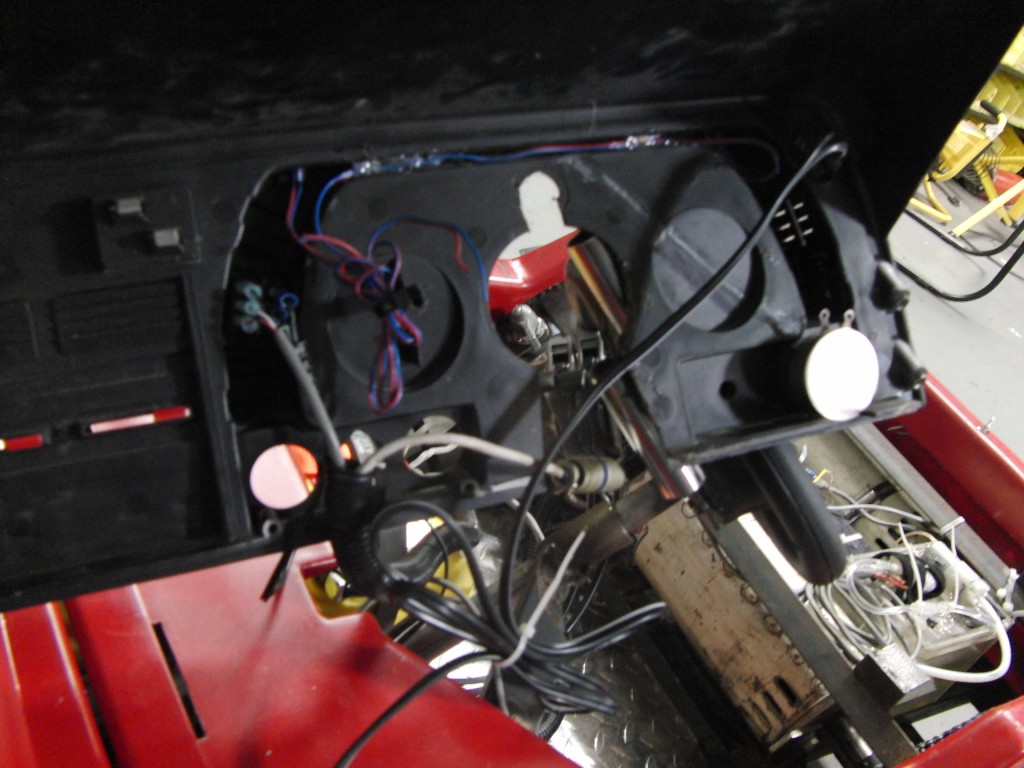

The steering wheel features a red horn button, a white cooling water button (because the red cap fell off in detroit), and a thumb throttle. The steel grips make it look like you are holding the stock wheel when driving, and add stability when doing massive wheelies. The original reverse switch on the dash is functional.

Nice and neat under the dash. Now.. lets take that top off….

The chassis is made almost entirely from steel bedframe angle iron. All of which was salvaged from the side of the road and contributes very little (if anything at all?) to the $500 budget! It was designed along with steering geometry using advanced prototyping equipment (a whiteboard and many many pieces of crumpled paper), before a single cut or weld was made. The late season addition of bumpers were made from regular tube steel, and coated in Noodle(tm) brand foam noodles. When you need a foam noodle, only go with the best….thing the dollar store has that day.

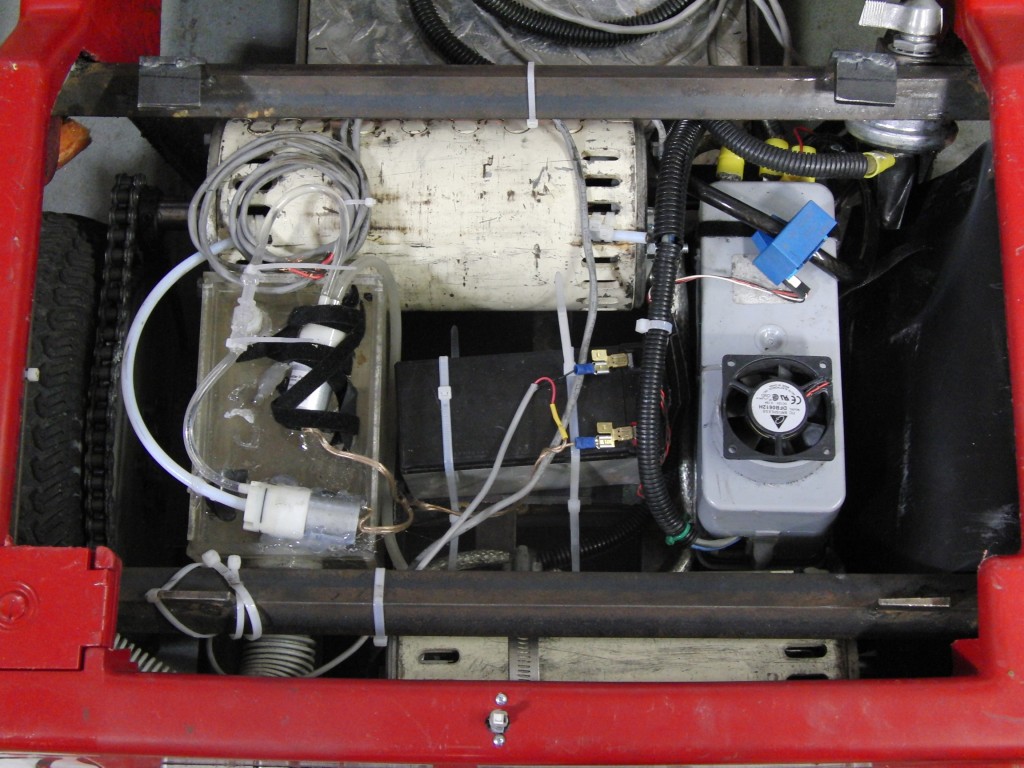

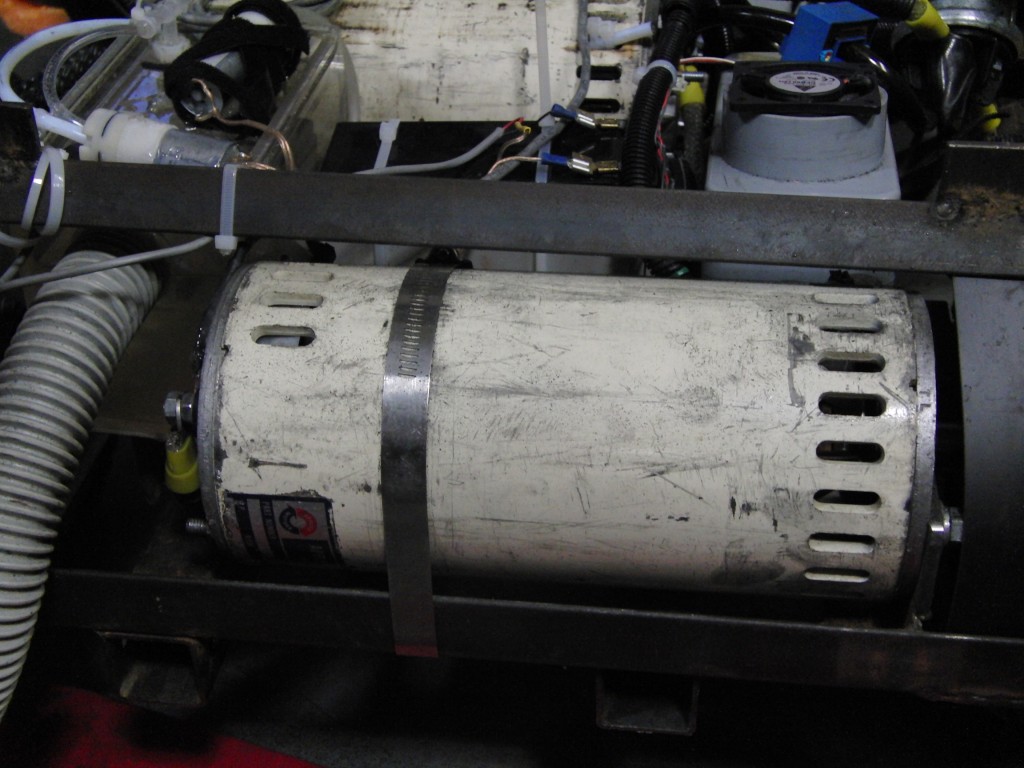

Taking a closer look under the seat, you can see our two permanent magnet motors, the water cooling box with pumps, a 12V accessory battery, and the motor controller. In the upper right is our safety cutoff (Had to go to a truckstop to find one rated for enough current that didn’t melt!)

The motors are ~1HP permanent magnet 36v motors scrapped from a very interesting electric lawnmower, last sold in 1975. This may be a difficult part to find…. Modern motors are much smaller, and much more efficient. But this one was big, free, and powerful! It is rated to draw 37A continuous, and 100A peak. After a quick bypass of its internal circuit breaker, and the addition of water injected directly on the rotors, they were able to eat many times their factory rating in current. This is not a recommended use for a long-duration installation, but its insane enough to work for at least one racing season.

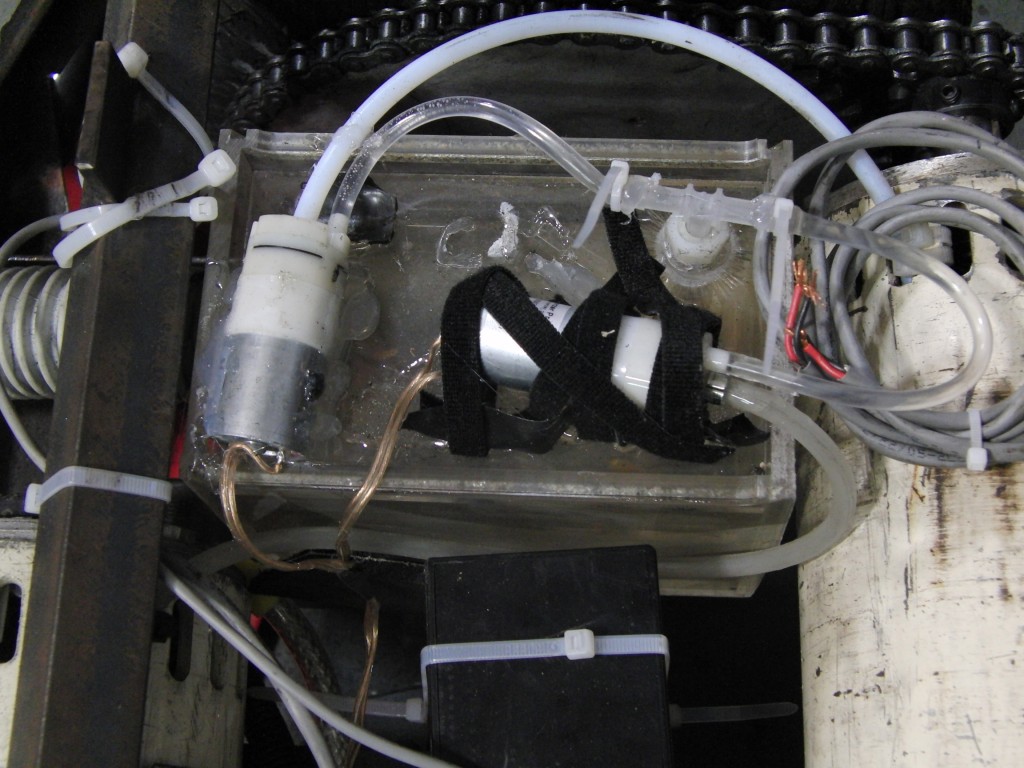

Water cooling was provided by a custom made box, with two tiny pumps. The filler tube for the water tank is routed to the original gas filler cap! The attachment system for pump #2 is completely proprietary, and its secrets have not yet been revealed, even to us. Water is called on demand, from temperature readings provided by the telemetry system. [Estimated completion date January 2013] Or a button on the steering wheel activated when you start to smell smoke.

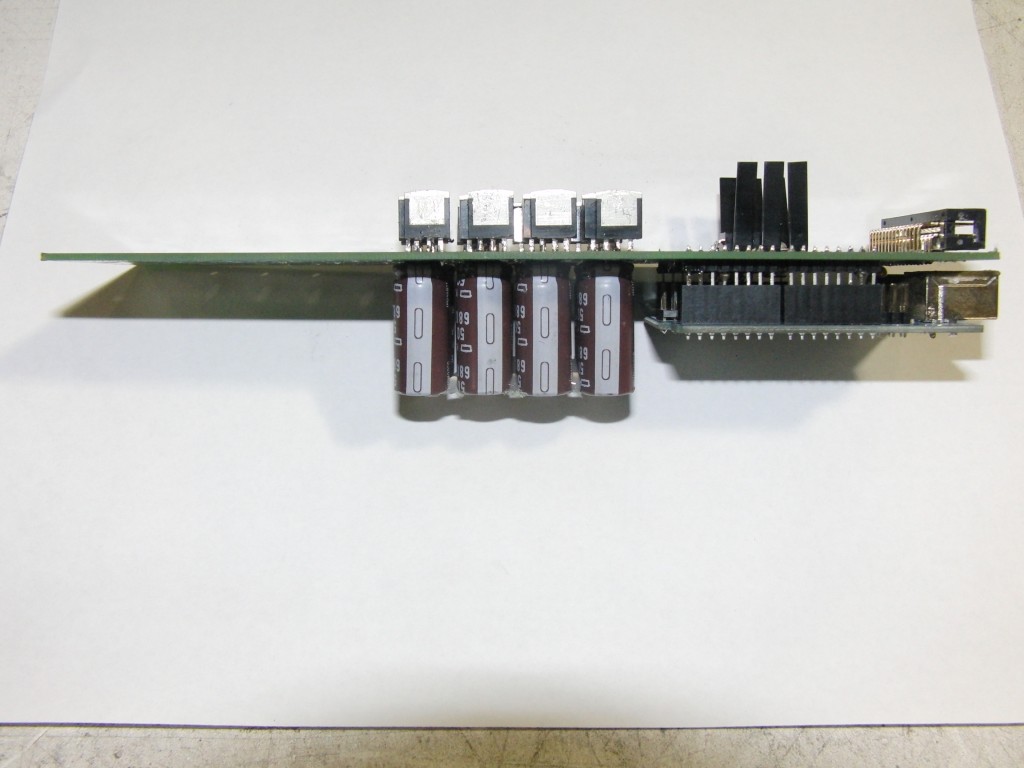

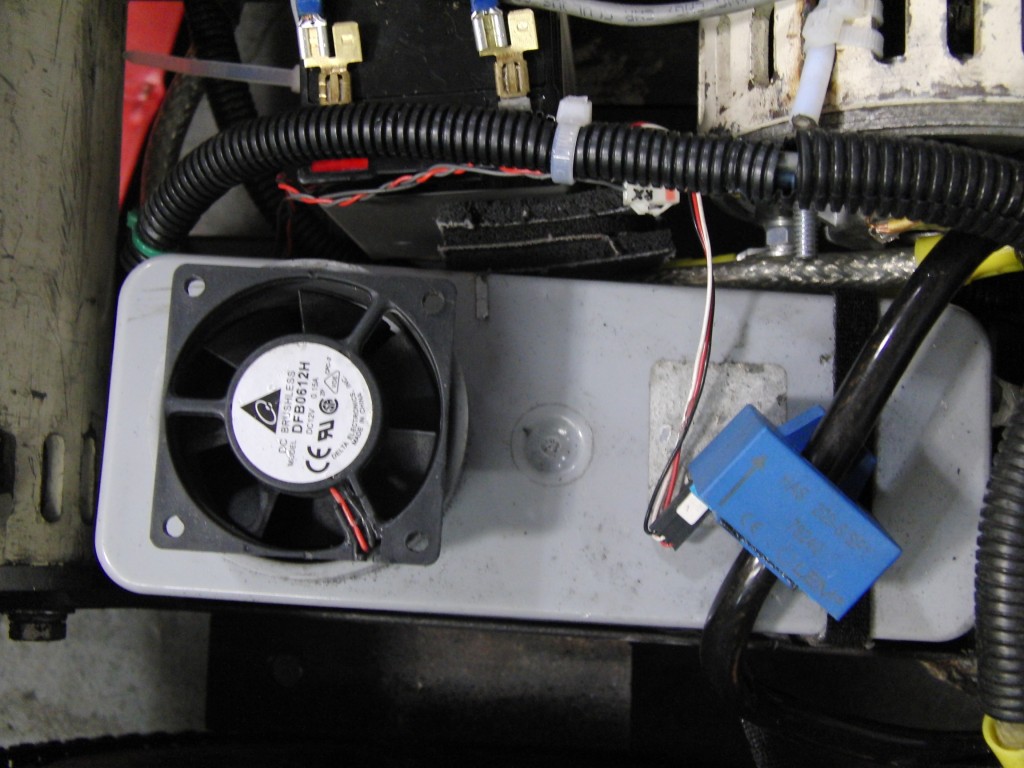

The most secret of Sector67′s secret sauce is the custom designed motor controller, affectionately dubbed “Paragon” by its creator, Alex McLees. Worthy of its own posts, in the very near future we will be publishing a lot of details of this controller, some lessons learned, advice for other power wheels teams, and maybe even where you can get your hands on one. The cost savings of building your own motor controller are astronomical. A professional controller at this rating would easily cost $300-$400. The BOM for this design, including circuit board fabrication, was around $80. There are several great open source motor controllers out there already, and we hope to be able to add to the pool in a fantastic way.

The Paragon was designed to be an Arduino shield, allowing fine control over acceleration rates, throttle response, regenerative braking parameters, as well as many types of fault detection through the simple to use Arduino interface. The Arduino signals an Allegro IC to drive four quadrants of MOSFETS capable of forward, reverse, and regenerative braking. In its currently built state, it is rated for 480A (continuous) @36V. The controller is shown with and without its integrated bus/cooling bars installed.

We downloaded a sprocket from the internet. Seriously. We downloaded a sprocket CAD file from a supply catalog, and cut it out on our CNC out of a piece of scrap aluminum plate. Living in the future folks! Building relationships with local machine shops has been a GREAT source of friends, and stock metal for projects. God bless those that call 12″ squares of 1/4 aluminum plate “scrap”.

Our wheels are handcart tires from harbor freight, often found on sale for $5.99/each, including rim, tire, tube, and bearing. The ‘bearing’ failed after about 100ft of acceleration, and was replaced with a “real” bearing for about $8/wheel. The two rim halves were welded together for extra stability, and the chrome paint was added because studies have shown chrome rims to be at least 6% more moxious than any other color.

For safety reasons, the horn is wired to its own 9v battery, on a short wire to the steering wheel. To prevent driver error, and to increase ire from other racers, the horn is also connected to the reverse input of the motor controller.

The steering system is made entirely from threaded rod, cursing, and science. Don’t let the materials and appearance fool you, this is a valid attempt at Ackerman steering geometry, and it worked so well on last years car we decided to try it again. Its my favorite example of turning junk into beauty of our build. If you lack a welding ninja to make one from scratch, pre-built go-kart spindles are available quite cheaply (<$20), and can get an identical effect. The brakes are bicycle disc brakes, and functioned as emergency brakes. The regeneration braking from the motor controller were the only brakes used during racing.

One final touch is an attachment system at the back, for a wheelie bar, trailer hitch for our stereo, and the most moxie filled thing Sector67 has even done, launching a parachute during the drag race.

It was so great to once again get to reach out and meet so many great people from so many other hackerspaces. We owe the power racing series a huge debt for making that possible. I hope we have been able to give some inspiration for next years race too. The power racing series is a fantastic opportunity to learn about electric vehicle technology, and vehicle design in general. They certainly don’t teach you how to make cape-friendly drive trains in college.

Fantastic writeup, Joe! Thanks.

Superb build! The secret water cooling pumps may have salvaged from a (top secret) automotive windshield washer fluid pump…..Ingenious!

Awesome post!

I do have a few comments though… 😉

The Power Racing Series web site describes it as such: “The challenge — to create a working electric vehicle for less than $500 using open source tools and tech…” yet you say “The attachment system for pump #2 is completely proprietary.” So how can a proprietary system be used when “open source tools and tech” are required?

And your batteries… a $300 value that it appears you got for free. That leaves just $200 for the rest of your build… but since you seemed to have scavenged bit and pieces from elsewhere (or got them donated) I can only assume the *value* of your can is much more than $500.

Now, I know we’re all scavengers to some degree, but you guys seem to take it to a new level… I’m not saying it’s unfair but… perhaps you’d consider starting to “share the wealth” as it were, which will ensure that you don’t get bored next year, and actually have a fair challenge against your competitors who lack the free/donated/scrounged materials you seem to have in abundance.

Anyway. congrats on the wins, and think over that last bit… 🙂

The pump attachment system line is a gag. you can see in the pictures that its a bunch of velcro zip ties haphazardly installed. The actual attachment system is hot glue 🙂 I was attempting to keep a little moxie instead of being strictly technical.

PPPRS rules about cost do not allow “sponsored” or “donated” items to skip the bill! The batteries are $150 each x3=$450, and counted at half value per PPPRS rules @$225. the motor controller was $80. leaving the remainder of the balance to cover the motors (??? they were $41 in 1975, I dont know if we should inflation-adjust that up, or devalue them down to the near-$0 practical value they have. they were quite literally scrap), frame, and thats about it!. the brakes are quite expensive as well($60-$80/each) , but do not count for the cars value per PPPRS rules (all “safety equipment” is exempt). I have a hard time making our car worth /more/ than $500! How much is a 12″ square plate of aluminum with a gouge in it worth? ($4/lb scrap?) How much is a bit of discarded chain from a factory worth? ($0.20/lb scrap?) How much are bent up rusty bedframes worth? If theres something else i’m missing, i’m not sure… but a vast majority of the car came from things that have little value, on purpose, to take the challenge to its full extent.

PPPRS is something we scavenge for the entire year 🙂

I would like to think that this post *is* the sharing the wealth post, just the lite version. There are no secrets left unexposed to the Fauxrarri that I am aware of, I even gave away the super secret source of our motors 😉 (Expect very detailed information about the motor controller soon as well) If theres other specific areas that would be of interest, im sure I could prod the guys on the team into writing more about them.

I would love to do more writeups about how we work with local businesses to turn their “scrap” into amazing member projects every single day though. I think its a great way to not only find materials, but to build local relationships in the community. We have people who call *us* when they throw cool stuff away now. instead of vice-versa. They want to see what amazing things we will make with it.

Well done… I plan to do a lot of studying before I attempt to build a car. I’m just hoping to avoid fires.. If I can avoid fires, that will be as good as winning in my book. (Not an engineer!)

Also, what the heck is up with those bumpers? Was another car sporting rotating knives on their hubcaps or something??

Too much torque! we had *so* many flat tires without the bumpers