Inspiration

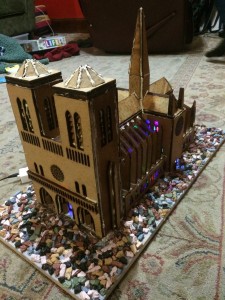

Growing up every year my family had a tradition of gingerbread house making. We always tried to out-do the previous year’s effort. This year my family decided we would try to achieve my lifelong dream of making the Notre Dame de Paris cathedral out of gingerbread, but with a twist: we’d use the laser cutter at Sector67, our beloved local hackerspace, to cut out the pieces. We’d done simple gingerbread structures before on the laser cutter so we knew it was feasible, but we weren’t sure if we could pull off a much more complex structure.

Design

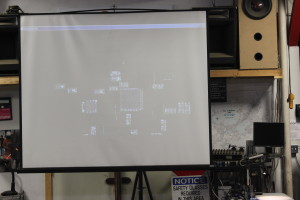

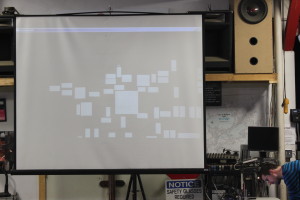

We were lucky enough to be able to start with a Canon papercraft model. That gave us a starting point for

dimensions, but the papercraft designs are meant to be made out of paper which can bend around corners and has basically no thickness. As a result we had to significantly redesign a model, removing lots of detail, segmenting curved parts and generally accounting for a material thickness, in our case 3/16”. It took about 20 hours using Inkscape to make a workable design, and the final SVG file is available at:

http://www.thingiverse.com/thing:1174128

That SVG file was made using Inkscape and so assumes 1″ = 90px. You may need to scale appropriately if you use different tools.

Testing

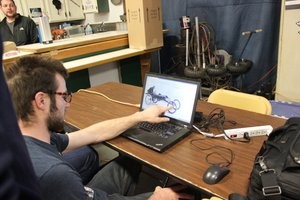

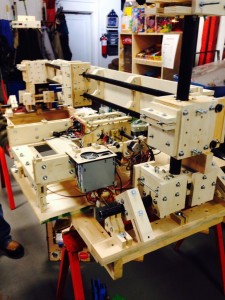

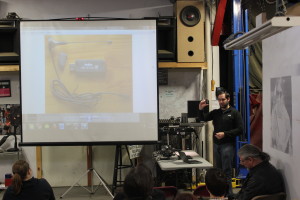

After completing the design we cut and assembled a complete prototype from 5mm luan plywood. This let  us not only confirm fit (there were problems that needed to be fixed!) but also get a feel for how the actual structure would go together.

us not only confirm fit (there were problems that needed to be fixed!) but also get a feel for how the actual structure would go together.

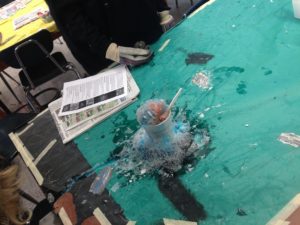

We also had to test many iterations of stained glass windows. Our vision was to melt colored sugar for the windows, but we went through about six iterations or different processes before we settled on something that really worked well.

Even baking the gingerbread required testing, to find the right thickness and to make sure the recipe worked well.

Mixing, rolling and baking

I’ve included the recipe we used below along with some instructions. We needed 10 sheets of 12″x18″ gingerbread, and each sheet took about half an hour, much of which was rolling it down to the desired thickness.

Cutting

Every laser cutter is different and if you are interested to try this you’ll have to figure out your own settings. I had to cut the gingerbread a bit slower than a similar thickness of plywood.

Stained glass windows

As mentioned above, we melted sugar to make the stained glass windows. We tried several approaches:

Brushing the sugar into the window openings and then baking the whole thing was not as consistent as we would have liked and resulted in the cut pieces of gingerbread shrinking and warping.

Using a cooktop/griddle with the sugar brushed in caused similar problems.

Using a cooktop/griddle with the sugar brushed in caused similar problems.

We made sheets of “stained glass”, and thought about frosting them to the backs of the windows, but with the fit of some of the pieces this was not feasible.

Aluminum foil, parchment paper and Silpat (silicone) mats all worked well enough to stop the sugar from sticking. In the end the process we settled on was to sprinkle sugar onto a silpat mat in the pattern needed to fill the windows. We pre-mixed a bowl of different sugar colors to provide a rainbow effect. We then baked the sugar on the Silpat at 350F for about 15 minutes, watching for when the sugar is just fully melted but not caramelizing. Catching it at just the right time left the colors well separated. We then pulled the Silpat mat with the melted sugar out of the oven, lined up the window openings and pressed the gingerbread pieces into the melted sugar. We then left heavy flat pieces of metal on top of the gingerbread pieces until the sugar cooled, as otherwise they would warp.

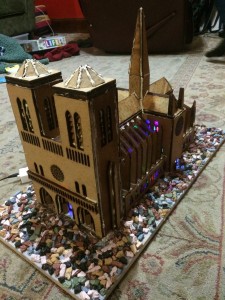

As you can see in the pictures, this process resulted in an accurate stained glass look that can be nicely lit from behind.

Building

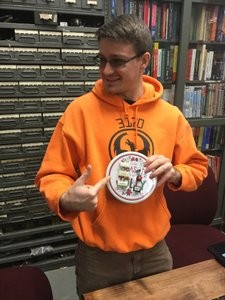

The time lapse video shows the assembly process. It took about 10 hours total as a two adult/two kid process. We used a simple royal frosting recipe that provides lots of holding strength and dries relatively quickly.

Lighting

We used a 16′ string of RGB LED lights to light the inside of the whole structure. The lights need to be strung while the structure is being built, and the design includes holes for routing the lights.

Challenges

Gingerbread can be a tough medium to work with. It can crack, warp and shrink. Even with our post-bake rolling process pieces were often not exactly 3/16″ thick and so for certain parts we needed to sand or grind to get a good fit. We ended up using an xacto knife, dremel cut-off wheel, hack saw and bench grinder at various times to make the model fit well.

This is an achievable family project but it was fairly time consuming. In the end we were all very happy with how it turned out!

More information including a complete recipe for the gingerbread sheets can be found at:

https://hackaday.io/project/8660-laser-cut-gingerbread-notre-dame-cathedral

us not only confirm fit (there were problems that needed to be fixed!) but also get a feel for how the actual structure would go together.

us not only confirm fit (there were problems that needed to be fixed!) but also get a feel for how the actual structure would go together.