This week in Sector67 brought us many interesting projects and most importantly our first aluminum casting!

A Dr Seuss character was replicated in real life:

A Porsche Carrera headlight was disassembled to determine repair possibilities:

A Porsche Carrera headlight was disassembled to determine repair possibilities:

A bundled Xbox Kinect has a specialty connector that required a clever double sided connector to add 12V power to the USB data and 5V power:

A bundled Xbox Kinect has a specialty connector that required a clever double sided connector to add 12V power to the USB data and 5V power:

The MakerBot received an upgraded build platform that required some surface mount soldering practice with a household skillet assisted by a heat gun:

The MakerBot received an upgraded build platform that required some surface mount soldering practice with a household skillet assisted by a heat gun:

Lastly, what you’ve been waiting for – the older kiln was prepared to melt aluminum and equipped with a PID controller:

Lastly, what you’ve been waiting for – the older kiln was prepared to melt aluminum and equipped with a PID controller:

The first step is the slice up aluminum stock into segments small enough to fit in the crucible:

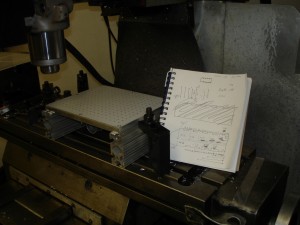

Setting up the kiln and the mold:

Setting up the kiln and the mold:

After dry rehearsing the pour before opening the kiln:

After dry rehearsing the pour before opening the kiln:

The kiln top is lifted to reveal a 1925*F 1975*F molten aluminum crucible:

The kiln top is lifted to reveal a 1925*F 1975*F molten aluminum crucible:

The crucible is extracted and carefully poured into the prepared mold after slag is removed from the top:

The crucible is extracted and carefully poured into the prepared mold after slag is removed from the top:

The crucible is then returned to the kiln to cool with the firebrick:

The crucible is then returned to the kiln to cool with the firebrick:

The casting is then opened to reveal the part:

The casting is then opened to reveal the part:

The casting was a quarter, nickle, and penny hot glued to a wooden block with a draft to determine the resolution that is possible with oil-bonded sand:

The casting was a quarter, nickle, and penny hot glued to a wooden block with a draft to determine the resolution that is possible with oil-bonded sand:

Relatively poor planning led to a number of small defects where sand fell away from the mold, but for the most part detail was well preserved through the process and we should be well equipped for the next test, lost foam casting:

Relatively poor planning led to a number of small defects where sand fell away from the mold, but for the most part detail was well preserved through the process and we should be well equipped for the next test, lost foam casting:

Just as an FYI, the aluminum pour temp was actually 1275 F.